Electrical and Electronics Association (BMEEA)

The BMEEA is made up from manufacturers and waterside dealers who provide advice, sales, installation and service of electronic and electrical equipment.

Dealers and installers regularly attend manufacturers' courses, ensuring that they are up to date with the latest products and installation techniques to the high standards of the BMEEA Code of Practice.

The Association has also developed a national qualification - BMET (British Marine Electrical Technician) specifically for the installation and service of electrical equipment. Additionally, it has the MEI and AMEI qualifications (Marine Electronics Installer) for the installation of electronic equipment.

The BMEEA was formerly known as the British Marine Electronics Association (BMEA) until October 2013.

Why should you use the services of a BMEEA Member?

Not all installers follow factory guidelines.

Some use unapproved materials, incorrect cable sizes, or improper fusing.

Some fail to commission the system or calibrate the equipment correctly.

Some don’t even offer a warranty on their workmanship.

BMEEA Approved Dealers and Installers are different.

They are selected because they do the job professionally — and they do it right.

Chair

Steve Bruce

Becoming A Member

Being part of a trade association gives your business a sense of credibility among other trade businesses as well as in front of the consumer; you are recognised as an organisation that adheres to Standards and Codes by displaying the BMEEA/British Marine logos. There are many benefits of joining British Marine membership. Here are our top five!

1. Training & Development

- Discounted sector-specific training courses that keep our members up to date with the latest products, installation methods and the high standards of the BMEEA Code of Practice, along with reduced rates on sector-specific training leading to recognised BMEEA-certified Marine Electrical or Electronics Installer qualifications

2. Business Support

- Unlimited 24/7 access to a professional legal helpline

- Access to a dedicated dispute-resolution service

- Crisis-management support when you need it most

- Expert VAT guidance to help you stay compliant

3. Marketing & Promotion

- Use of the British Marine association logo and sector-specific qualification badges to demonstrate professionalism and credibility

- B2C and B2B visibility through the ‘Find A Marina’ listing

- Access to British Marine promotional assets for enhanced brand recognition

4. Networking & Collaboration

- Sector specific networking opportunities and events

British Marine Membership

Join TodayMeet our Committee Members

Join Today

Marine Electronics and Electrical Training

The BMEEA has established training programmes and qualifications that allow the development of engineers and to recognise their achievements.

We are committed to ensuring that the quality and expertise of our members is appreciated by customers and boat-builders.

An important part of this is to establish training and qualifications that allow the development of engineers and to recognise their achievements.

Changes to the association bye-laws meant that all relevant organisations needed to have at least one qualified member of staff at each of their premises where there is more than one by January 2011 to retain their membership.

The committee is also acutely aware that if the Association doesn’t get standards and qualifications in place itself, they may be forced upon us by some external body.

The potential costs of this and the lack of relevance are a real threat. British Marine Electrical Technician (BMET) accreditation is a scheme that has been introduced to recognise the qualifications and experience of those involved with the installation of electrical supplies in boats.

The scheme consists of a two-day course followed by a multiple-choice examination and verification of a candidate’s practical competence.

Also, for the correct electronic equipment installations, there is the Marine Electronics Installer (MEI) course for engineers who have sufficient basic previous practical experience but who need to be up to speed in associated Standards and the all-important digital interfacing.

The MEI is also available at an advanced level (AMEI) that takes into account even more technical requirements from the installation and usage points of view.

By choosing a company with staff that has attained BMET and MEI/AMEI accreditations, you can be confident that you will get the highest standards of workmanship and expertise.

See below for more details. As a member, course fees are cheaper:

Rogues Gallery

Below are examples of work done by traders who were not professionally qualified to undertake the work. Thankfully, BMEEA members were called upon to fix the work before too much damage was caused.

This connection, required for a battery cable extension, was wrapped in masking tape, immersed in a bilge covered in petrol.

- Incorrect method of protection of the joint – inadequate protection both electrically and mechanically for the joint.

- Incorrect method used to join the two cables together – P clips can loosen and reduce pressure on the joint – this could create a high resistance and hence generate heat and potential failure to carry heavy current. There has been no attempt to try to splice the multistrand cable to try to improve the contact surface between the two cables.

- Incorrect location of cable join – exposed to flammable liquids – major fire hazard if the joint loosens and then overheats as current passes through.

The corrective action would be to refer to the current BMEEA code of practice with regards to the correct method of joining large, multistrand, high current carrying cables, the correct means of joining such cables, the correct protection of such connections and correct positioning of such connections to ensure the connection is correctly positioned to avoid direct contact with liquids – especially highly flammable liquids, to ensure the connection is mechanically and electrically secure and adequately protected for the environment in which it is located. If in any doubt, a suitably qualified and experienced electrical engineer should be engaged to carry out the work in a professional manner in accordance with industry standards.

Always be sure to use the appropriate size connectors and cable junction boxes and always ensure the cables are correctly fused for the size and current capacity of the cable.

This picture of an engine starter battery illustrates how NOT to connect multiple cables to the battery posts.

The errors include:

- Too many terminations onto a single stud

- Incorrect sized cable lugs on the end of cables

- Exposed conductors

- Missing or inadequate insulation

- Battery not secured in place

At best the outcome of the above would be poor power supply to the equipment connected in such a way, resulting in intermittent operation or poor performance. At worst, there is the possibility of cables pulling loose from the incorrect terminations and flopping against other conductors or surfaces causing a dead shot with consequent catastrophic battery discharge, leading to damage batteries, damaged equipment and possible fire hazard, in addition to which, electric shock is always a possibility.

Further information on the correct installation of cabling and termination as well as best practices can be found in the BMEEA Code of Practice 5th edition available through British Marine

This photograph indicates the damage that occurs when non qualified personnel install equipment without reading instructions or understanding the equipment they are working with.

In this case a 200 Amp Shunt was installed in a circuit that drew 300+ Amps, the shunt clearly overheats and the causes the protective cover as well as the cable insulation to melt and breakdown, possible end result could trigger catastrophic failure at the very least and expensive repair which will need to be carried out by qualified and professional engineers.

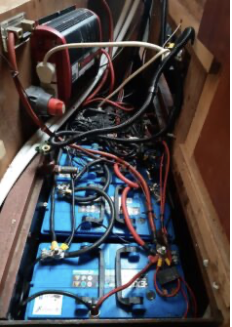

The batteries were originally installed in an enclosed compartment, unfortunately this leaked and so the batteries were sitting in a bath of fresh water, the installation had not been planned correctly and wiring had been added to as well creating a potential fire hazard due to the possibility of short circuits being caused by the insulation chafing through – exposing live conductors.

The water leak indicated poor maintenance schedules and lack of attention. The second picture shows the installation after being corrected by a qualified BMEEA member, excess cabling removed, correct terminations and connections used, cables re-routed and correctly supported and secured, battery compartment drained and cleaned. Regular maintenance inspections were also instigated to ensure no repeat of the leaks and to ensure the batteries were in good health.

This installation in a Leisure craft shows the damage caused to an inverter, although it was allegedly installed following the installation instructions it was apparent that no DC protection was provided leading to a catastrophic overload and a subsequent overheating event.

Also in the picture, a coil of blue mains type cable can be seen coiled and strapped to the bulkhead, this is also poor practice, since coils of cable can generate significant heat when current is flowing and this can also lead to overheating of the insulation, with potential for combustion and possible fire.

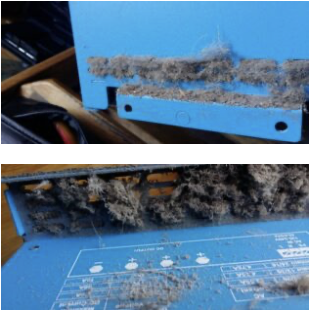

The presence of this amount of dust and fibre inside equipment can block ventilation pathways, will cause equipment to overheat, leading to possible malfunction or even trigger a combustible event.

Regular maintenance by qualified and approved service dealers can ensure equipment is regularly inspected and tested, will remove the risk of excessive heat build-up and ensure the equipment installed onboard will operate reliably over the course of many years.

Fuses are provided for a very good reason – safety. They are designed to enable equipment to operate to its correct specification and they will fail should the equipment become overloaded and create a risk of fire due to overheated components or wiring.

Replacement of the fuse with an incorrectly rated fuse or with any alternative conductor will create a situation where the equipment and associated wiring is no longer protected against overheating and will cause a potential fire risk.

A professional installer will always use the correct style of connector to link cables to equipment.

The connection method shown in this picture will at best give rise to an intermittent display on the instrument, at worst, if the connection carries high current – the connections could spark providing a source of ignition and possibly trigger a fire onboard.

For connections like this, a spade connection should always be used.

A qualified and professional installer will always plan the installation, they understand how important it is to check behind every surface onto which equipment is going to be mounted to avoid situations like this.

At best this would require rewiring several cable looms in the locker behind, at worst, these cables could be live 240v mains cable - possibly giving the drill operator an electric shock, damaging other electrical equipment onboard or possibly triggering an electrical fire with consequent damage to the boat, in extreme cases even complete loss of the boat.

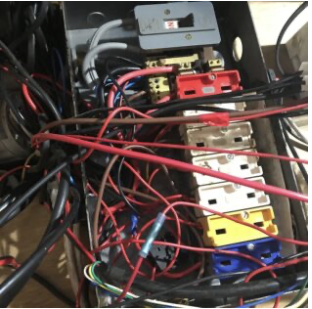

This is a fire risk and a serious potential electrocution danger, using a domestic rewireable fusebox as a junction box with exposed contacts and confused unlabelled cables is a recipe for disaster, with personal injury risk, fire hazard, equipment damage and property damage all likely.

This is absolutely why a qualified, competent installer should be used to ensure the installation complies with current regulation and guidelines in the Code of Practice available to professional marine installation and service engineers.

This is a classic example of amateur installation capabilities, poor planning of location of equipment to be mounted inside the hull, with no regard for structure of the surface or the thickness of the hull.

Wrong choice of fixings and appalling workmanship has resulted in the hull of this boat being destroyed, this

Being a planning hull, the area of hull is now weakened, the hull in the region of the screw holes will craze and crack and any filler used to fill the holes will simply fall out, leading to water penetration of the glass fibre laminate and probably water ingress to the hull, a professional hull repair is now required and this will be an expensive repair before the boat is fit to go back into the water.